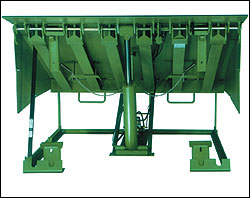

Kelleys HK Dockleveler provides full hydraulic operation with single push-button activation.

|

Unique Kelley open frame design.

|

|

|

Patented Lambda Beam design and construction.

|

|

|

Full hydraulic operation with single push-button activation.

|

|

|

4 diameter ramp cylinder mounted at front of ramp for maximum

strength and efficiency.

|

|

|

Totally enclosed non-ventilated, unitized hydraulic pump and motor

assembly with single hose per cylinder for longer life and lower

maintenance costs.

|

|

|

Automatic retracting 60,000 lb. structural steel dock level support

legs for full unrestricted working range.

|

|

|

Self-cleaning, lug-type lip hinge with lifetime warranty.

|

|

|

Four fixed rear hinges for maximum support and no pinch points.

|

|

|

Full operating range toe guards with OSHA-required yellow markings per

ANSI-Z535.

|

|

|

Integral maintenance strut and separate lip lock hold ramp and lip in

raised position for service or cleaning.

|

|

Model

|

25,000 lb. Capacity

|

30,000 lb. Capacity

|

35,000 lb. Capacity*

|

40,000 lb. Capacity

|

45,000 lb. Capacity*

|

50,000 lb. Capacity

|

|

HK6x6

|

1,360 lbs.

|

1,460 lbs.

|

1,460 lbs.

|

1,612 lbs.

|

1,612 lbs.

|

1,669 lbs.

|

|

HK6x8

|

1,648 lbs.

|

1,761 lbs.

|

1,761 lbs.

|

1,943 lbs.

|

1,943 lbs.

|

2,028 lbs.

|

|

HK6x10

|

2,007 lbs.

|

2,132 lbs.

|

2,132 lbs.

|

2,345 lbs.

|

2,345 lbs.

|

2,456 lbs.

|

|

HK6.5x6

|

1,453 lbs.

|

1,557 lbs.

|

1,557 lbs.

|

1,656 lbs.

|

1,656 lbs.

|

1,714 lbs.

|

|

HK6.5x8

|

1,739 lbs.

|

1,860 lbs.

|

1,860 lbs.

|

1,991 lbs.

|

1,991 lbs.

|

2,076 lbs.

|

|

HK6.5x10

|

2,154 lbs.

|

2,293 lbs.

|

2,293 lbs.

|

2,461 lbs.

|

2,461 lbs.

|

2,572 lbs.

|

|

HK7x6

|

1,549 lbs.

|

1,657 lbs.

|

1,657 lbs.

|

1,793 lbs.

|

1,793 lbs.

|

1,851 lbs.

|

|

HK7x8

|

1,843 lbs.

|

1,972 lbs.

|

1,972 lbs.

|

2,143 lbs.

|

2,143 lbs.

|

2,227 lbs.

|

|

HK7x10

|

2,300 lbs.

|

2,454 lbs.

|

2,454 lbs.

|

2,666 lbs.

|

2,666 lbs.

|

2,777 lbs.

|

*Reinforced

Consistent with our policy of continuing product improvement, we reserve the right to change these specifications

without notice or obligation.

Dockleveler rises when shielded push-button is pushed and held. Lip section hydraulically extends as ramp reaches top of travel.

Button is released. Ramp and lip lower to truck bed. Dockleveler is ready for use. Store dockleveler prior to truck departure.

In stored position, dockleveler is fully supported by dock level support legs.

Ramp may be lowered to fully supported below-dock level position, without extending lip, to service low trucks with end loads.

|

6' and 8' long models - 24, 12 above dock to 12 below.

|

|

|

10' long models - 30, 18 above dock to 12 below.

|

|

|

12' long models - 34, 20 above dock to 14 below.

|

|

Unitized ramp with 50 KSI yield deck plate, 50 KSI yield beams and 55

KSI yield lip.

|

|

|

Self-cleaning, lug-type lip hinge with lifetime warranty.

|

|

|

Fully welded subframe.

|

|

|

Fixed rear hinge provides 4 of side-to-side tilt without forming

gap at rear hinge.

|

|

|

Unitized pump/motor assembly.

|

|

|

Four-way tread plate on ramp and lip.

|

|

|

Control box dimensions 12W x 8H x 4D.

|

|

Side and rear weatherseal.

|

|

|

Foam insulated ramp.

|

|

|

Abrasive, skid-resistant ramp and lip surface.

|

|

|

Galvanized (spray-metalized) ramp, lip and frame to resist corrosion.

|

|

|

18" or 20" lip. Recommended for use when servicing

refrigerated vans.

|

|

|

Independent lip extension and hydraulic stop buttons.

|

|

|

Black- and yellow-striped toe guards.

|

|

|

Explosion-proof electrical controls. Consult factory with class,

division and group.

|

|

|

Self-forming pan.

|

|

|

Minimum lip bend for use with material handling equipment with low

underclearance.

|

|

|

Automatic return to dock.

|

MOTOR: 1 hp TENV control panel: Heavy-duty shielded push-button with rotary on/off switch in NEMA 12 enclosure.

|

Curb angle sets.

|

|

|

Side and rear weatherseal.

|

|

|

Self-forming pans.

|

|

|

Self-contained frames.

|